18 Dec Manufacturing Execution Systems (MES): The Missing Link

You’ve implemented a popular brand of ERP software. Your PLM system is humming like a well-tuned sports car. You have CAD/CAM and TMS and toolpath simulation software in place, and all your people have been trained on its use. You’ve spent boatloads of money on software and consultants, have all the correct systems in place, and yet you blew an important delivery date last week and you still walk out to the shop several times a day to check on jobs. What gives? Chances are good that it’s time to take the next big step towards production nirvana by implementing a Manufacturing Execution System (MES).

Think of it as the missing link between ERP, the shop floor, and all the other software systems used to manage a manufacturing business. MES provides a higher level of production visibility and job tracking than ERP. It makes real-time scheduling truly real-time. It offers previously unattainable access to performance and quality data, along with the analytical tools necessary to improve both.

Let Me Count the Ways

MES does all this and more, but what it doesn’t do is fall into any neat, easily-defined software category. In fact, a Google search for MES software returns a host of “Best MES Software” results, a few of which lead to suppliers who can probably spell MES but that’s about all. Searches will find long lists of MES features such as data collection, master production scheduling, labor tracking and so on, functions that any ERP system is probably already doing. Even to those who are knowledgeable about software systems, MES can be a little confusing.

Someone well-equipped to help navigate this murky territory is Andrew Robling, senior product manager at Epicor Software Corp., Austin, Texas. For him, there’s nothing confusing about MES, or the benefits it brings to companies large and small.

“MES admittedly means many things to many people, but at its heart it’s about collecting data directly from equipment and machine tools so that you can make better decisions,” he said. “That data might be as basic as machine status or how many parts it’s produced so far today, and from there extend to true process monitoring, capturing values like machine temperature and pressure, or part quality data for SPC [statistical process control] purposes.”

Data collection can be automatic, he noted, with integration to a machine-mounted PLC (programmable logic controller), for instance, or completely manual in the form of shop floor touch screens and mobile devices. This flexibility might help to explain why many in the industry struggle to offer a clear-cut definition of MES, and why its capabilities vary from vendor to vendor. Ambiguous or not, however, there’s one thing that everyone agrees on—if seeking to increase visibility to the inner workings of a production floor and thereby improve manufacturing efficiency, MES is an excellent way to get there.

Get Real (Time)

Consider one of the most important of all shop floor management activities, accurate job scheduling. According to Robling, MES makes it possible to keep the wheels on the production bus, rather than finding out it crashed sometime yesterday afternoon. “Shops need a mechanism to display job information in real time, to let people know that the equipment isn’t operating as it should, or that a cutting tool is about to fail,” he said.

With MES, this can be accomplished in a variety of ways. It might be a management-level dashboard that turns red if there’s a problem, or Andon-style displays (visual control devices) on the factory floor that provide information on current machine status, production levels and non-conformance warnings. Robling said some shops will even send alerts through the company’s public address system. “Whatever approach is used, these systems give people an opportunity to take corrective action immediately, possibly avoiding hours of inefficient machine operation.”

MES is not only for automotive production levels. Robling agreed that MES is more common with larger manufacturers, but noted that even small job shops can enjoy significant benefits—in fact, these are often the ones who gain the most.

“We worked with a shop in Pennsylvania recently that figured their OEE level [overall equipment effectiveness] was somewhere in the mid-60s,” he said. “After implementing MES, they found that the handful of machine downtime instances they were manually recording each day were in reality much higher—on the order of a couple hundred small interruptions per shift that the operator didn’t bother reporting. The result? Their OEE was roughly 15 percent lower than expected. MES not only provided visibility to this problem, but also the data needed to address it.”

What About MOM?

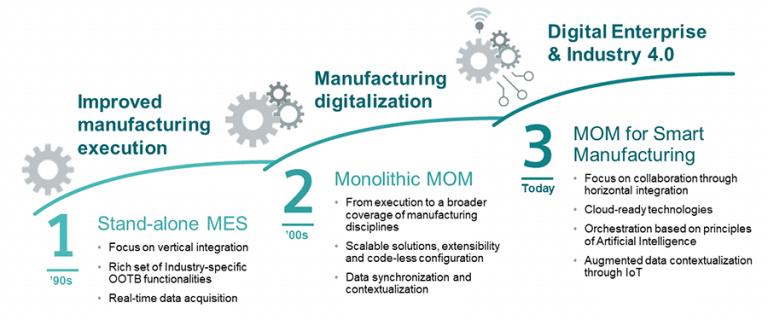

Investigations into MES often find a related term, Manufacturing Operations Management (MOM). Subba Rao, innovation officer for the manufacturing operations management group at Siemens Digital Industries Software, Plano, Texas, explained that MES can be thought of as a smaller, less comprehensive version of MOM, at least from a Siemens Digital Industries Software perspective.

“MOM is broader,” said Rao. “Where MES is focused more on real-time data collection, MOM leverages that data for quality management, maintenance activities, closed-loop collaboration on engineering information for the factory floor, and orchestration of the various processes needed to produce quality products. We like to call it the digital brain for production operations, one that delivers insight and transparency to all involved.”

He also explained that, compared to even five years ago, MES and its big sister MOM are easier than ever to implement, thanks in large part to Industry 4.0 and the IIoT (Industrial Internet of Things). That’s because today’s CNC machine tools as well as other types of industrial equipment are typically chock full of sensors that detect everything from axis loads to spindle vibration. These sensors are simple to connect and more than happy to share data with external software systems, allowing all manner of predictive maintenance, process monitoring, and improvements to occur.

Simplified connectivity is great, Rao noted, but it is what is done with the data that counts. “Operators, machine programmers, production control supervisors and everyone else involved wants to know what’s being worked on right now, how the shop is performing, and how processes could be improved for current and future product innovations,” he said. “But that’s just a small slice of what MOM brings to the table. Everybody in the company is looking for better ways to perform certain tasks, whether it’s the quality control team that wants to analyze statistical trends or the logistics manager who needs to stage material. MOM, and to a lesser extent MES, helps to facilitate the coordination and orchestration needed to achieve truly efficient manufacturing.”

Optimized Results

Hold on though—what if delivery and quality levels have been running at 98 percent or higher for the past two years? What if setup times are about as good as can be expected, especially, say, in an a low-volume, high-mix environment? And, say as well, that shop floor scheduling and “orchestration” are well in hand. Why upset the apple cart?

Good question. It’s entirely possible that in this example, a machine shop or a sheet metal fabrication business has no need for the advanced functionality discussed here, and that the data collection and job tracking that come standard with most ERP systems—what many in the industry actually label as MES—are all that’s needed to continue hitting at the current “home run” level.

But consider this information from ECI Software Solutions, Fort Worth, Texas, which suggests that MES takes production efficiency to an entirely new level.

Many ERP systems do a decent job in scheduling, at a macro level. But what about when a shop is bending 20-gauge stainless steel sheet, or cutting slots in titanium with a ½” [12.7-mm] end mill, and wants to know all the other available jobs that share those attributes so that it can leverage the same setup and tooling? MES provides an opportunity to optimize work centers based on whatever values the shop wants, and then communicate the updated schedule back to the ERP system, so that everything is working in a harmonious fashion, according to the company.

This is something that most ERP systems can’t do on their own, according to ECI, because they don’t have the necessary machine interfacing or access to engineering information. MES does, though, resulting in far greater machine utilization, less scrap, and shorter setup times. And because a properly-implemented MES captures in-process data such as equipment loads and inspection results, substantial process improvement opportunities exist that would otherwise have been unattainable. The bottom line? MES is a good place to start an Industry 4.0 initiative.

Goodbye Tribal Knowledge

Of course, machine optimization assumes the engineering data is actually available, and that it is clean, well-organized, and all in one place. For many shops, especially those without a formal engineering department, however, this information is scattered about on tooling sheets and programming systems, or resides in the heads of the veteran machinists and sheet metal fabricators who’ve been making shop floor magic happen for the past 30 years. The question then becomes, what happens when these valuable employees either retire or leave the company?

In many ways, this is MES’ true value. It acts as the central repository for all of the documents, drawings, and instructions needed to set up and operate manufacturing equipment. It then monitors the performance of that equipment, manages the production and quality-related data coming out of it, feeds that data back to the company’s other software systems, and gives humans the opportunity to identify ways to improve processes and machine utilization.

In short, MES does what people have been doing for as long as there have been buttons to push or levers to pull. It eliminates the intuition and gut feel that far too many shops rely on every day, turning what would otherwise be tribal knowledge into a corporate asset, according to ECI.

The Big Poka-Yoke

At its most basic, MES is about control and the ability to error-proof processes, and through that error-proofing avoid production problems, according to Mike Hart, director of product strategy for manufacturing and industrial IoT at Plex Systems Inc., Troy, Mich. “It’s about connecting the dots.”

Those dots might include a job’s tooling and raw material requirements, he said, as well as its planning and quality control expectations. There’s what’s running now, what’s running this afternoon, and what’s running next week to consider, and what impact these activities will have on inventory levels. MES ties these often disparate sources of information together to create a connected organization. It gives operators easy access to the tools needed to be effective at their jobs, while management obtains a more coherent view of their business systems, together with the information needed to make smart decisions.

Increased visibility is great, but how does MES help to make processes error proof? “Because if you know who’s performing a certain process or running a certain machine, you can then use that information to find out what training they’ve received, and whether they’re qualified to do the job,” Hart said. “But even more than that, MES makes certain that all the proper control plans are in place and that people are ‘checking the boxes’ at the correct times and places. If they don’t, red flags are immediately raised—not tomorrow, not when the job is done, but right now.”

Shifting Gears

If MES is so great, why haven’t more shops invested in it? For that matter, why is there so much industry focus on ERP, when it seems like the real benefits come with an MES implementation? At the risk of stating the obvious, ERP is a requirement for practically any manufacturing company, or at least any company with more than a handful of employees and an eye towards growth.

Simply put, ERP pays the bills. Literally. Accounting functions such as payables, receivables, tax reporting, and more would be exceedingly difficult without ERP software, as would inventory control, shipping and receiving, sales order management, purchasing, and the all-important MRP. ERP systems also boast some level of scheduling and shop floor control functionality, even though most fall short on managing its inner workings. Hence the need for MES.

“We’ve seen it go both ways, but yes, some shops choose to pursue an MES strategy first,” Hart said. “It really depends on what pain points they’re experiencing. If there are problems, for example, with material traceability, or the shop is facing quality challenges and they want to shine a light on what’s happening out there at any given moment, they’ll typically start with MES. That said, one of the key benefits of MES is the potential integration with ERP and other manufacturing systems, so it’s important to keep that in your sights as you move forward.”

Say Hello to the Emperor

Bear in mind that implementing MES raises many of the same considerations and potential pitfalls as ERP. “There’s no point in doing it unless your data’s correct,” said Jim Errington, executive vice president of sales and service for Fujitsu Glovia Inc., El Segundo, Calif. “I tell this to ERP and MES customers alike, that no matter how great the system or how super its tools, filling it with bad data will only provide bad answers.”

Errington shared a story of a customer he worked with recently. After spending months cleaning up its bills of material and routers, they flipped the switch on the factory planning side of their MES software, only to overload a critical work center. The problem? No one noticed the inaccurate move times. “Like many shops, they never had a real scheduling system, so these values were never looked at,” Errington said. “Everyone was aware that you can’t move a two-ton casting instantaneously, but in this case, that’s exactly what they told the system to do.”

The oversight ended up putting them behind schedule by several days, he added, and took them weeks to recover from a simple mistake. This is why it’s so important to get the engineers and planners and costing people involved in any implementation—MES or otherwise—so as to avoid situations like this. “A lot of people say that data is king; maybe so, but that makes data accuracy the emperor,” said Errington.

His scheduling example illustrates one more important point about MES. Unlike ERP, MES is an elephant that can be eaten in small bites. For instance, it’s quite possible to implement only the scheduling function, as Glovia’s customer did, or integrate MES with the shop’s maintenance software for OEE tracking, or use it to collect production data on the automated laser cutter you just installed, or provide better information to the assembly line … the list goes on. Yes, data integrity and good housekeeping are equally important, but the effort will almost certainly be smaller and the ROI much faster.

The message is obvious: low hanging fruit abounds in even the best-run companies, and MES is the stepladder needed to pick it. “This will become increasingly clear as we move into Industry 4.0 and more companies want to collect and analyze the data coming off their machine tools,” Errington said. “MES gives us the ability to connect the factory with the rest of the business, providing real-time data, more accurate scheduling, greater machine utilization, and improved control over every aspect of the production floor. To us, manufacturing enterprise systems aren’t a nice-to-have—it’s a must-have, at least for any manufacturer that wants to remain competitive.”